After thirty-some filthy, intimate hours, there are twenty-five, flex-rated electrical conductors and a pneumatic hose running through Abe's center.

These cables will allow us to connect power, data, pressure, and vacuum to the end effector of the robot, while never having to worry about them becoming tangled during complex movements.

When robots leave the factory with these things pre-wired, the cables are placed while each massive axis is connected to the next. We dreamt about these scenarios, working at 4am, when our shoulders ached from contorting to reach cables our fingers could barely touch, and our hands bled from untrimmed flashing while struggling with deeply hidden bolts.

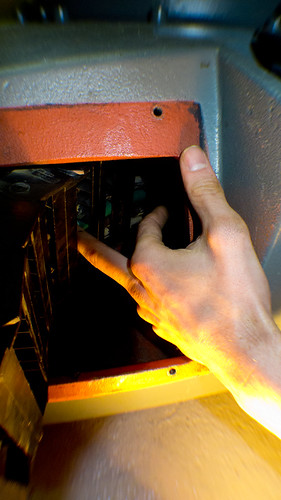

Above, you can barely see our green multi-conductor cable progressing through the some of the last steps of Abe's labyrinth. In a productive use of the middle finger, I'm helping our cable take the radius of the its carrier. Eventually, we succeeded in routing the cables through, and the (trying) labor seemed worth the several thousand dollars we would have spent having this done by the manufacturer.

Princeton Custom Robots

Forget hot rods and choppers: custom robots are where it's at. Abe recently got a good cleaning and a new coat of paint, and is starting to look rather sharp.

Next up is routing some cable and air hose...

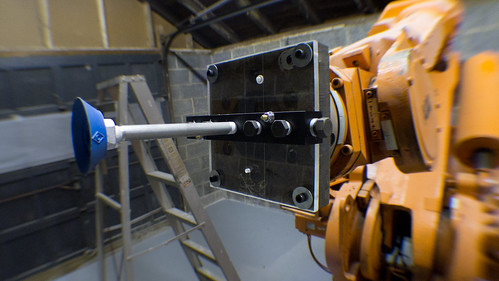

Drawing a Vacuum

This is our first end-effector for Abe, a vacuum gripper constructed primarily of parts from McMaster-Carr. Beautifully comical in appearance, it works amazingly well and can hold ceramic tiles with just a few inches of mercury.

Finally, we have what we need to start building.

Finally, we have what we need to start building.

Paying our dues, noses to the grindstone, et cetera...

The volume of our labor has always scaled with the scope of our endeavors, and on a rainy morning in October of 2011, we poured a concrete floor. When we finished, it was sleet instead of rain; by the time the concrete was twenty-four hours cured, a freak storm had left the Northeast buried in two feet of snow. Three months later, we're still cleaning up from that damn storm.

As any contractor, bag of concrete, or google search will inform you, even near-freezing temperatures prevent the cement in concrete from setting up properly. So thanks to the snow, the top few millimeters of our floor have been slowly returning to their original form - powder, and we've been blowing, sweeping, and vacuuming them up relentlessly.

We condemned a craigslist shopvac to the task, and though it struggled, it got the job done. We are now resurfacing with an epoxy floor coating. Straightforward, arduous, and again, totally complicated by the fact that it is winter in an uninsulated room.

In the future, this will be a blog of beautiful, dynamic, novel constructions. For now, it is a blog of mediocre home improvements.

As any contractor, bag of concrete, or google search will inform you, even near-freezing temperatures prevent the cement in concrete from setting up properly. So thanks to the snow, the top few millimeters of our floor have been slowly returning to their original form - powder, and we've been blowing, sweeping, and vacuuming them up relentlessly.

We condemned a craigslist shopvac to the task, and though it struggled, it got the job done. We are now resurfacing with an epoxy floor coating. Straightforward, arduous, and again, totally complicated by the fact that it is winter in an uninsulated room.

In the future, this will be a blog of beautiful, dynamic, novel constructions. For now, it is a blog of mediocre home improvements.

RTFM.

We've confirmed Abe actually functions. So now, we're taking several steps back to prepare.

Reading manuals, finishing the workspace (outlet covers! organization! heat!), making sure everything will be safe once work begins.

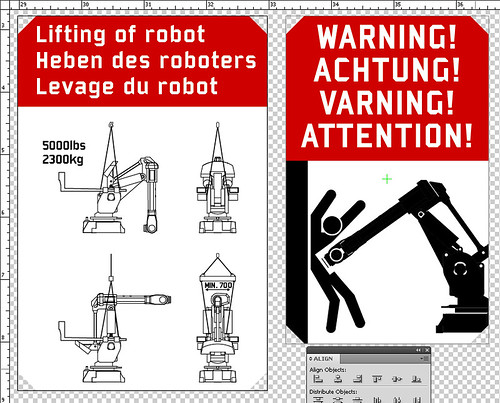

Part of that safety... is stickers. As delivered, Abe had four different generations of stickers, so for clarity and cohesion, we're making a whole new set to match a forthcoming color scheme. Unfortunately... designing retro-industrial graphics on the computer is the fun part... with that out of the way, we've got some frustratingly real paint buckets to use - while covering several hundred square feet of concrete with epoxy floor coating.

It continues.

Reading manuals, finishing the workspace (outlet covers! organization! heat!), making sure everything will be safe once work begins.

Part of that safety... is stickers. As delivered, Abe had four different generations of stickers, so for clarity and cohesion, we're making a whole new set to match a forthcoming color scheme. Unfortunately... designing retro-industrial graphics on the computer is the fun part... with that out of the way, we've got some frustratingly real paint buckets to use - while covering several hundred square feet of concrete with epoxy floor coating.

It continues.

Subscribe to:

Posts (Atom)